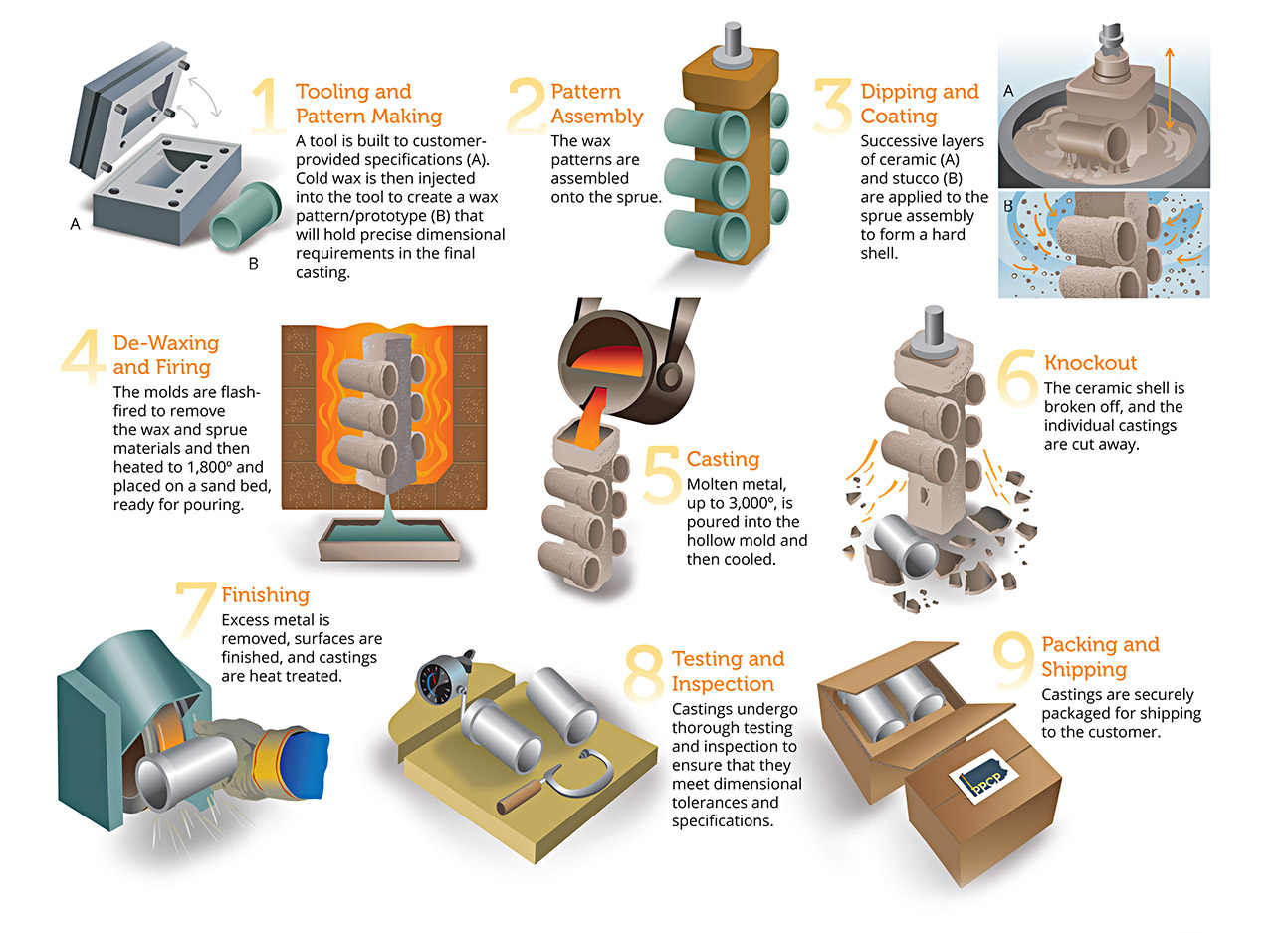

Investment Casting Process

In theory the casting process is just like photography. An image

is regenerated through the use of negatives and prints but in casting

negatives are molds and our prints are the castings parts.

Process of Investment Casting:

In the investment casting process, a wax pattern is coated with a

ceramic aterial, which, when hardened, adopts the internal geometry of

the desired casting. In most cases, multiple parts are cast together for

efficiency by attaching individual wax patterns to a central wax stick

called a sprue. The wax is melted out of the pattern – which is why it

is also known as the lost wax process – and molten metal is poured into

the cavity. When the metal solidifies, the ceramic mold is broken off,

leaving the near net shape of the desired part. At last, Finishing,

testing and packaging complete the process.